Introduction

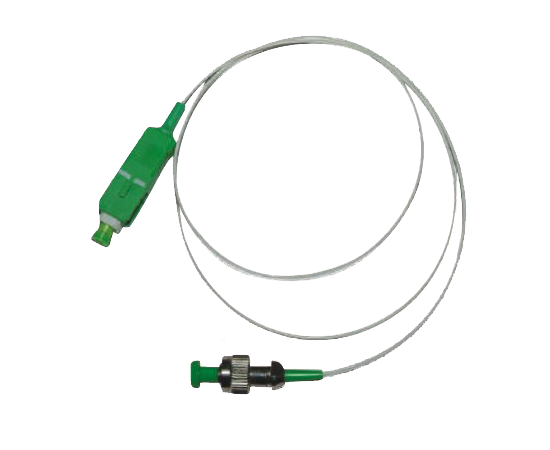

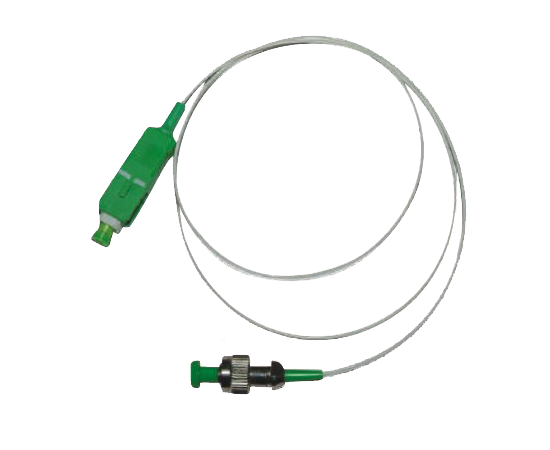

CAMTRONICS provides varies types of patch cords including ST, FC, SC, LC, SMA, MTRJ, MU and E2000 with UltraPolished (UPC), AnglePolished (APC) or other polish requirement, Singlemode or Multimode, Simplex or Duplex, 0.9mm, 2.0mm or 3.0mm cable available. With our excellent testing equipment, refined polishing machine, advanced polishing procedure and experienced technicians, we are proud to provide reliable and top quality patch cord at a reasonable price. Every patch cord supplied by us is guaranteed to be well polished and exceeds the industry standard.

Our patch cords are assembled with high grade connectors. The ferrules are made of zirconia from Japan. Apart from simplex patchcords,duplex patchcords are also available. All patchcords provided by CAMTRONICS are guaranteed to meet our specifications.

Feature

- Low insertion loss

- Low back reflection

- Environmentally stable and reliable

- Compliant with Bell core TIA/EIA and JIS

Application

- Telecommunications

- Local Area Network

- CATVFTTH

- Test equipment

| Standard of Topography Measurement of Polished Ferrule |

| Measurement Parameter | Pass/Fail Limits (Min) | Pass/Fail Limits (Max) |

| Radius of Curvature | 10mm | 25mm |

| Fiber Height (Spherical Fit) | -50nm | 50nm |

| Fiber Height (Planar Fit) | -10nm | 200nm |

| Apex Offset | 0μm | 50μm |

| Angle (In degree) | -0.3 | 0.3 |

| Fiber Roughness (Rq) | 0nm | 10nm |

| Fiber Roughness (Ra) | 0nm | 10nm |

| Ferrule Roughness (Rq) | 0nm | 10nm |

| Ferrule Roughness (Ra) | 0nm | 10nm |

| Diameter | 125μm | 130μm |

| Our products Performance |

| Connector Type | Insertion Loss

(Maximum)** | Insertion Loss

(Typical)** | Return Loss |

| General SM Connector | APC | <0.3dB | 0.15dB | >65dB |

| UPC | <0.3dB | 0.15dB | >50dB |

| General MM Connector | <0.3dB | 0.1dB | N/A |

| MTRJ SM Connector | <0.75dB | 0.2dB | >40dB |

| MTRJ MM Connector | <0.5dB | 0.2dB | N/A |

* Specification on one connector only.

| Length Tolerance |

| Length | Tolerance |

| <1m | +10cm/-0cm |

| 1m-5m | +10%/-0% |

| 5m-20m | +7%/-0% |

| >20m | +5%/-0% |

Optical Characteristics For Singlemode 9/1 25um

| Characteristic | Conditions | Specific Values | Units |

| Optical characteristics | | | |

| Attenuation | 1310nm | <0.36 | [dB/km] |

| | 1550nm | <0.22 | [dB/km] |

| Dispersion coefficient | 1285~1340nm | -3.0 to 3.0 | [ps/(nm*km)] |

| | 1550nm | <18 | [ps/(nm*km)] |

| Zero dispersion wavelength | | 1302 to 1322 | [nm] |

| Zero dispersion slope | | <0.091 | [ps/(nm*km)] |

| Polarization Mode Dispersion | | | |

| PMD Maximum Individual Fiber | | <0.2 | [ps/√km] |

| PMD Link Design Value | | <0.08 | [ps/√km] |

| Fiber cutoff wavelength λc | | 1180 to 1330 | [nm] |

| Fiber cutoff wavelength λcc | | <1260 | [um] |

| Mode field diameter(MFD) | 1310nm | 9.2 ± 0.4 | [nm] |

| | 1550nm | 10.4 ± 0.8 | [um] |

| Group index of refraction (Typical) | 1310nm | 1.466 | |

| | 1550nm | 1.467 | |

| Geometrical characteristics | | | |

| Cladding diameter | | 125 ± 1.0 | [um] |

| Cladding non-circularity | | <1.0 | % |

| Coating diameter | | 242 ± 7 | [um] |

| Coating/ cladding concentricity error | | <12.0 | [um] |

| Coating non-circularity | | <6.0 | % |

| Core/ cladding concentricity error | | <0.6 | [um] |

| Curl (radius) | | >4 | [m] |

| Environmental Characteristics | 131 0nm, 1550nm | | |

| Temperature dependence induced attenuation | -60ºC toº +85C | <0.05 | [dB/km] |

| Temperature-humidity cycling induced attenuation | -10ºC toº +85C, 90% R.H | <0.05 | [dB/km] |

| Damp heat dependence induced attenuation | 85ºC, 85% R.H, 30days | <0.05 | [dB/km] |

| Watersoak dependence induced attenuation | 20ºC for 30days | <0.05 | [dB/km] |

Optical Characteristics For Multimode 62.5/1 25um

| Characteristic | Conditions | Specific Values | Units |

| Optical characteristics | | | |

| Attenuation | 850nm | <2.7 | [dB/km] |

| | 1300nm | <0.6 | [dB/km] |

| Overfilled Modal Bandwidth | 850nm | >200 | [MHz*km] |

| | 1300nm | >600 | [MHz*km] |

| Numerical Aperture (NA) | | 0.275 ± 0.015 | |

| Group index of refraction (Typical) | 850nm | 1.496 | |

| | 1300nm | 1.491 | |

| Geometrical characteristics | | | |

| Core diameter | | 62.5 ± 2.5 | [um] |

| Cladding diameter | | 125.0 ± 1.0 | [um] |

| Cladding non-circularity | | <1.0 | % |

| Coating diameter | | 242 ± 7 | [um] |

| Coating/ cladding concentricity error | | <12.0 | [um] |

| Coating non-circularity | | <6.0 | % |

| Core/ cladding concentricity error | | <1.5 | [um] |

| Environmental Characteristics | 850nm, 1300nm | | |

| Temperature dependence induced attenuation | -60ºC toº +85C | <0.10 | [dB/km] |

| Temperature-humidity cycling induced attenuation | -10ºC toº +85C, 90% R.H | <0.20 | [dB/km] |

| Damp heat dependence induced attenuation | 85ºC, 85% R.H, 30days | <0.20 | [dB/km] |

| Watersoak dependence induced attenuation | 20ºC for 30days | <0.20 | [dB/km] |

Testing

In order to assure a satisfactory performance, a rigid testing procedure is applied to every patch cord assembled by us. The patch cord would be tested to ensure their repeatability and the exchange ability. The aim of this testing procedure is to make sure that every patch cord is in best condition before delivery.